QTS X430/X160 3D列印機

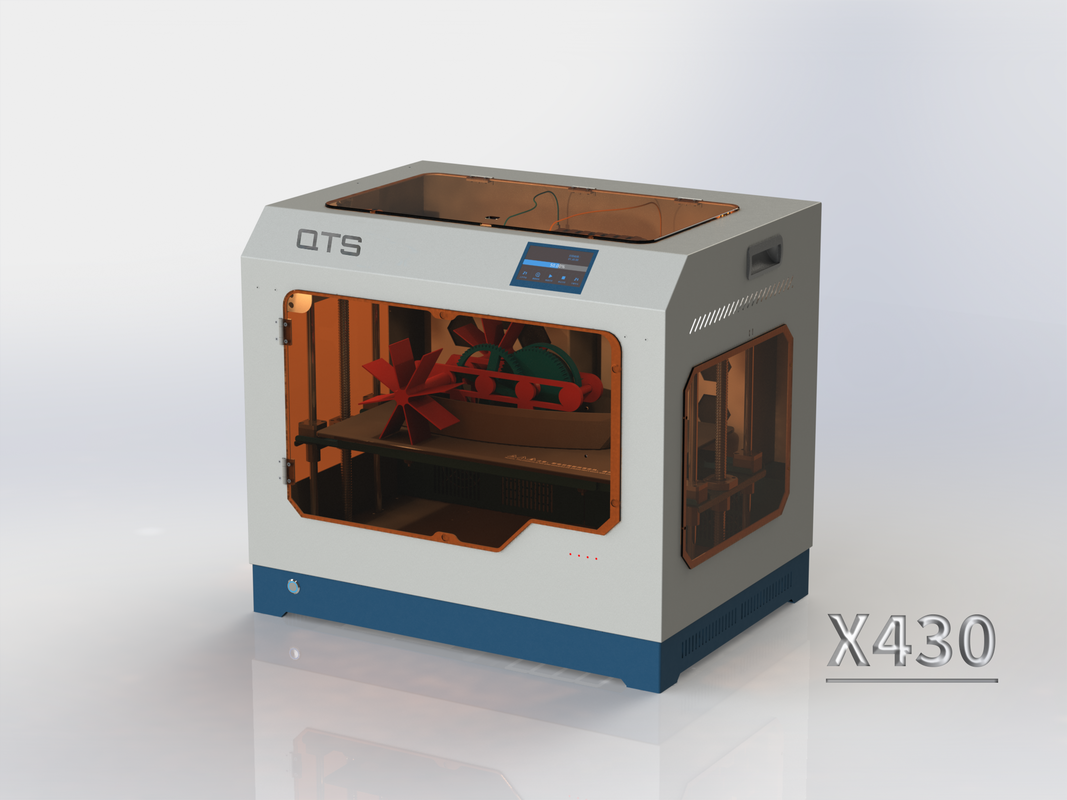

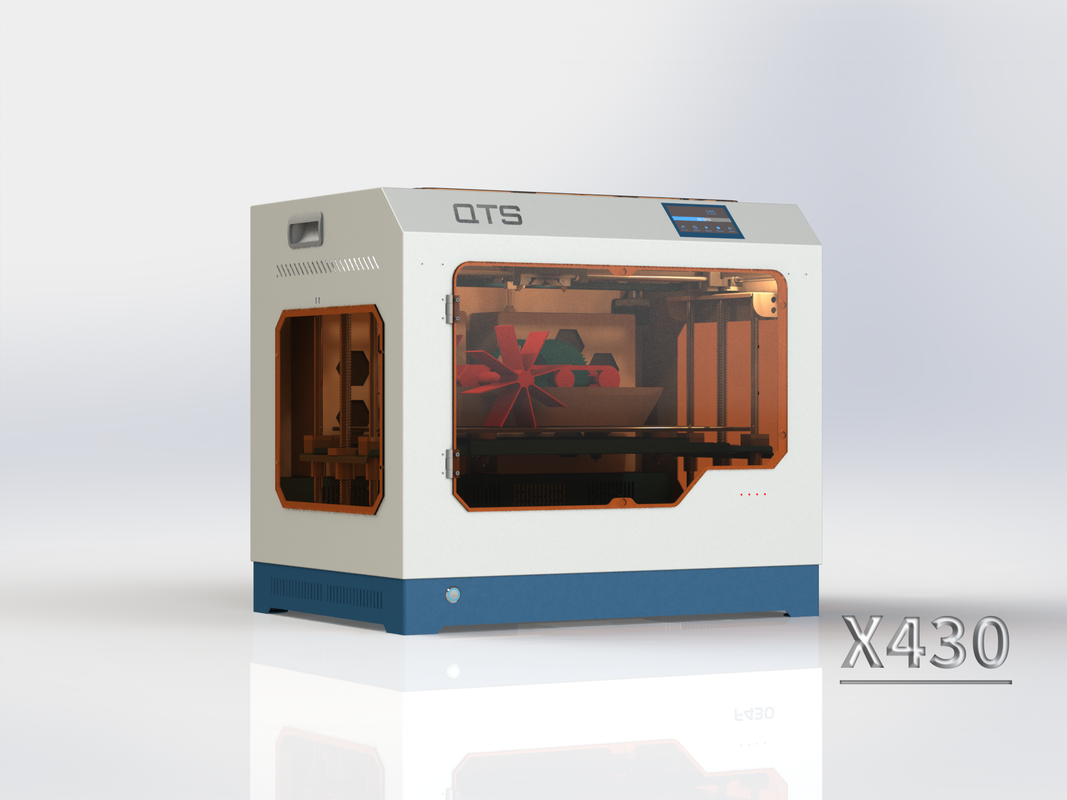

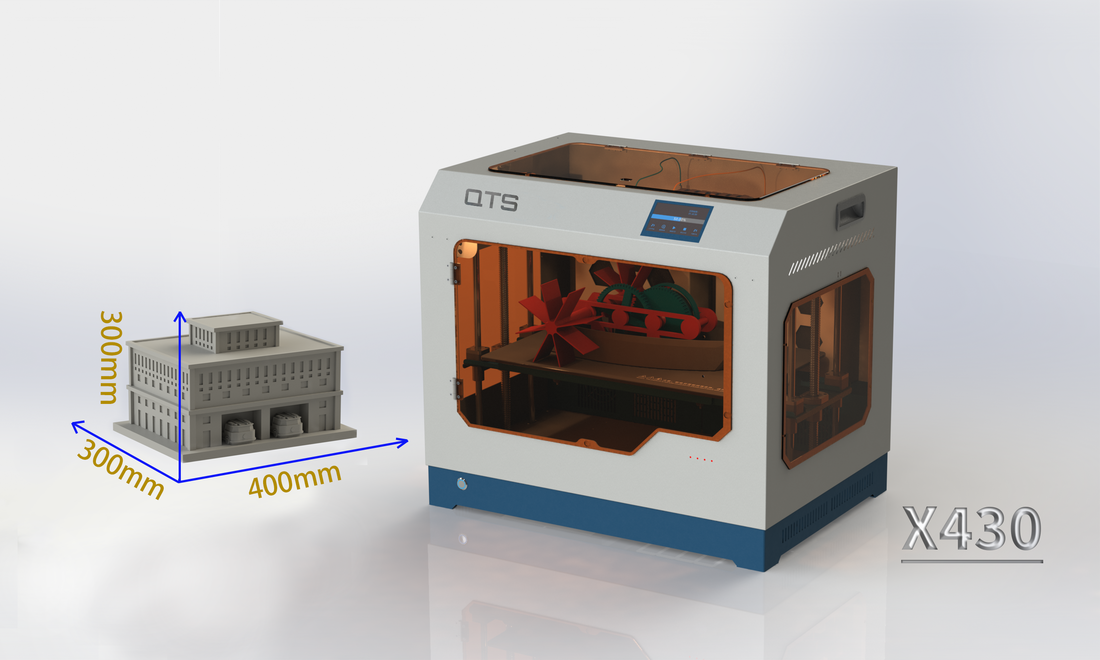

QTS X430 3D列印機

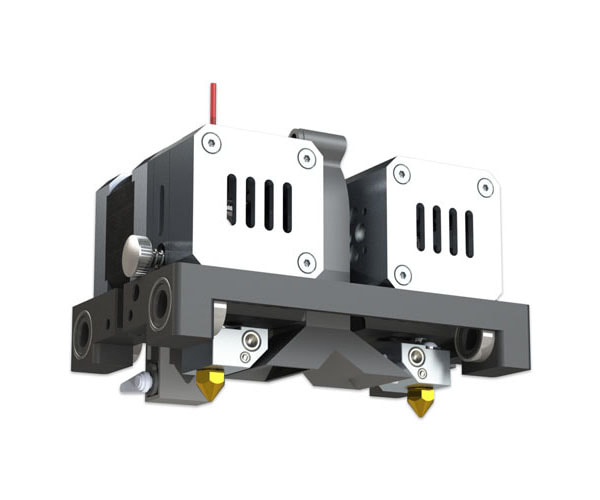

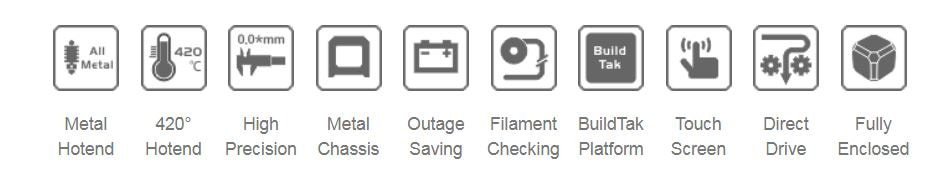

Support 420°C Hotend

支援 420°C 高溫噴頭

QTS Corporation publish 420°C high temperature nozzle to 3d printer market. X430 equiped with dual extruders and this kind of extruder allow to print with a variety of filaments. The nozzles height can also be micro adjusted. (Default support 260°C, contact us for 420°C.)

420° 高溫噴頭,獨家專利,全球首發。可支援列印多種耗材;支持雙噴頭,噴頭高度可手動微調。(默認 260°C,420°C 請先聯繫我們。)

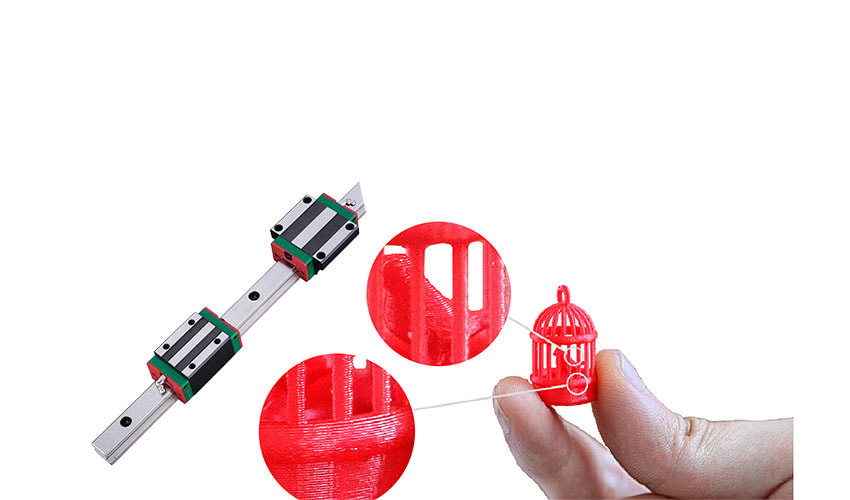

High Precision & High Speed

超高精度 & 快速列印

We exclusively research and develop the extruder feeding system and guide rail, which support high-speed printing. Its printing accuracy can reach high to 0.04mm,and it allows to extrude filament steady without block.

獨家研發送料系統、直線導軌模組,支援高速列印,列印精度高達 0.04mm,出料均勻,不堵頭

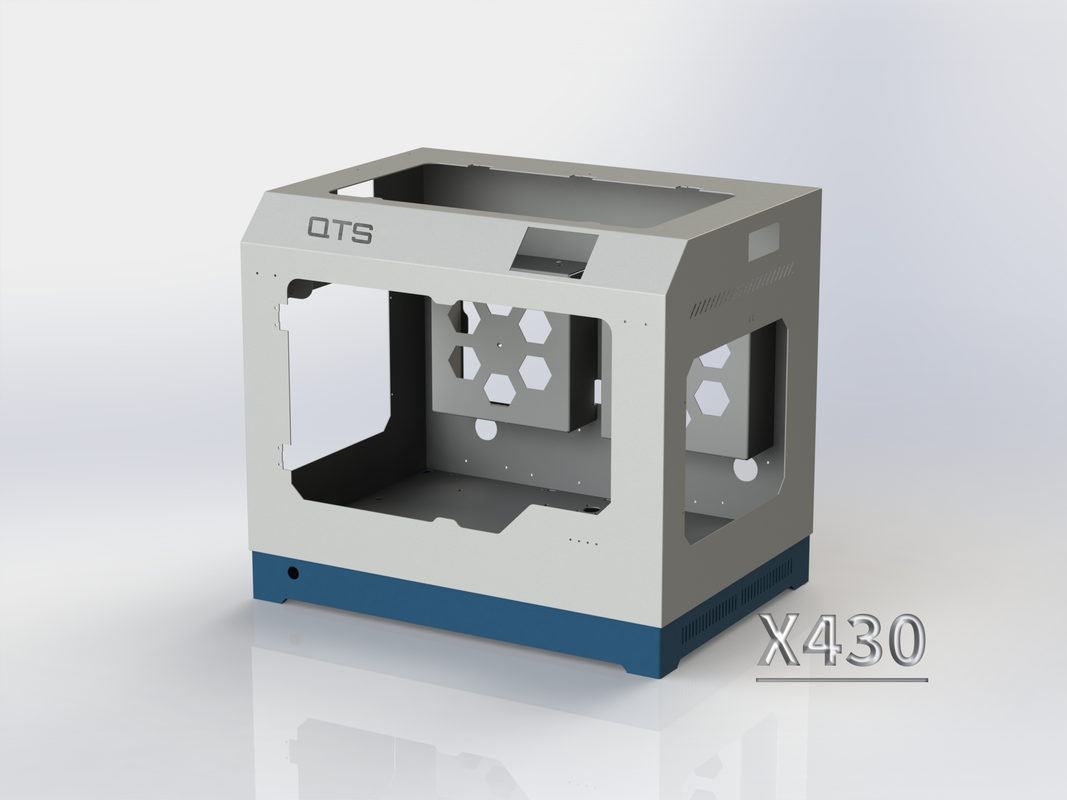

Stability

超強穩定性

The whole-steel body not only ensure the stability when printing, but also extend the usage period greatly. Its optimization and cooperation of overall structure ensure the sustainable and efficient operation. The first batch of QTS 3D printers have been working for 5 years and more than 8000 hours.

精鋼一體成型保證了機器的穩定性並極大延長了使用壽命。整體結構設計的優化和配合保證機器可持續高效運行。QTS 首批3D印表機已經持續工作 5 年,單台累計列印時間平均超過 8000 個小時。

Fully Enclosed High-Temperature Chamber

熱風全封閉高溫艙

Fully enclosed chamber can block all external interference and reduce noise. Hot chamber can provide constant room temperature so that model won’t deform when printing

全封閉主機殼內部溫度高達 70°C,使收縮率較高的模型如尼龍,ABS等不會翹邊或變形。且全封閉空間隔絕噪音和外界空氣影響,保證列印過程不受干擾。

Outage Restored & Filament Detection

斷電續印 & 耗材檢測

The printer will automatically memorize the current position and save print data. Lower the platform and withdraw filament when power off suddenly. It will continue to print from the last stopped point after power’s on.

The printer will avoid invalid printing by stoping print and warning when filament runs out.

The printer will avoid invalid printing by stoping print and warning when filament runs out.

意外斷電時印表機自動記憶當前位置,並儲存列印資料,降低工作臺並回抽。待電力恢復後從斷電處繼續列印。

耗材用盡後自動暫停列印,回抽耗材並發出提示音,避免無效列印。

耗材用盡後自動暫停列印,回抽耗材並發出提示音,避免無效列印。

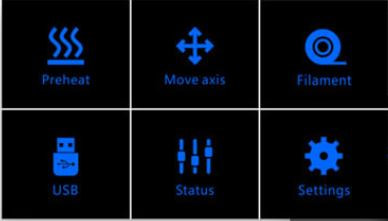

Touch Screen

彩色觸控式螢幕

The printer have all-English-menu touch screen which is easy operate and friendly use. One key to warm,one key to print as well as many other shortcut keys.

配備全彩中文觸控式螢幕,操作簡單,介面友好。提供一鍵預熱,一鍵列印等多種快捷操作。

CERAMIC PLATFORM

微晶面板

The printer has mico-crystal platform so that can support hight thermal efficiency, you can set the parameters to turn off the hot bed automatically after the specified number of layers.

微晶面板能夠高速熱傳導,節能環保。並且支援在指定層數後自動關閉熱床。

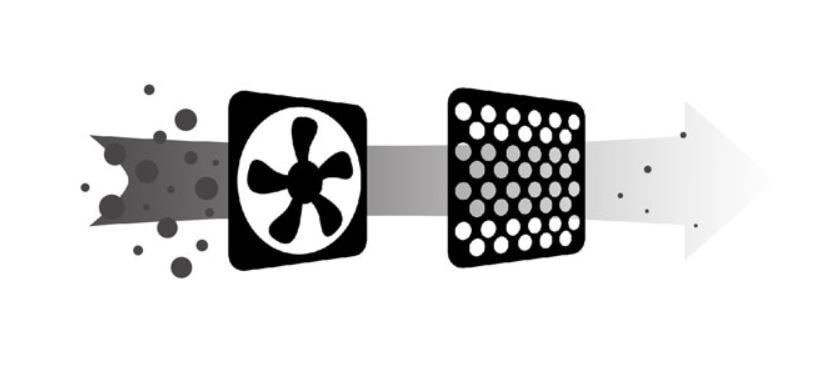

Air Filter System

空氣過濾系統

The air filter system can adsorb impurities and gases that generated by printing special filament, more safe and environmental protection which is more suitable for house, school, office space

空氣過濾系統可吸收列印時產生的雜質和有害氣體。安全環保無污染。是學校、家庭、辦公場所的首選。

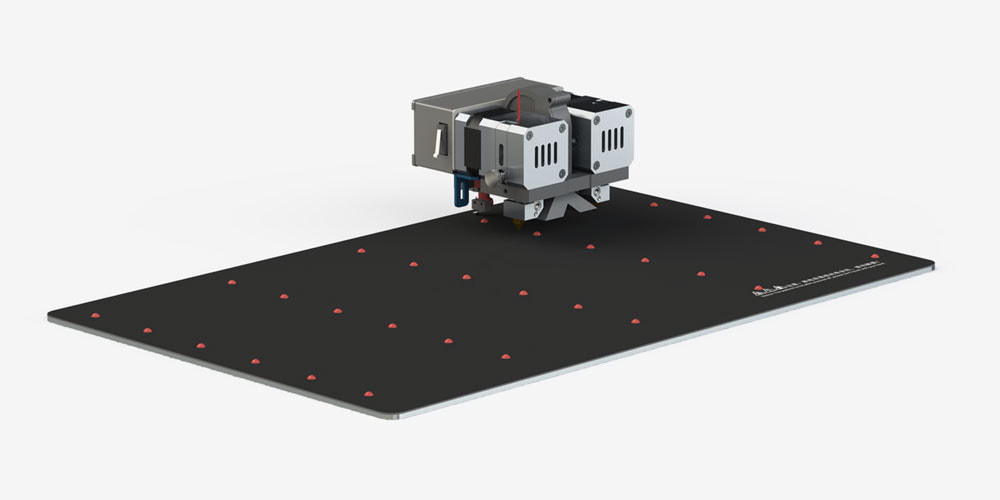

Automatic Leveling Platform

全自動調平熱床

Use of 25 points through the probe to save the level of platform flatness data at the initial, through the Z axis intelligent compensation table height in the printing process to achieve fully automatic leveling

使用初期通過25個探測點保存工作臺平整程度的資料,在列印過程中通過Z軸智慧補償工作臺高度,從而實現全自動調平。

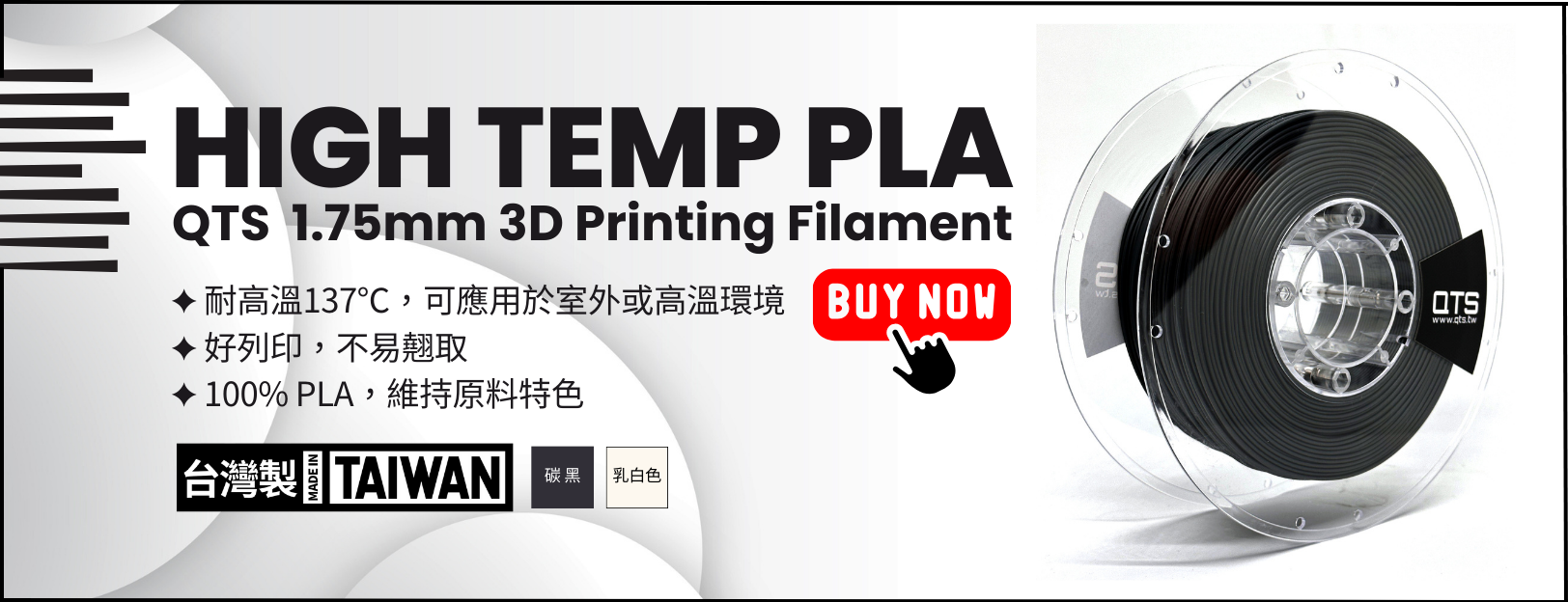

FILAMENT & APPLICATION

耗材與應用

The standrad X430 are able to print PLA,ABS,Nylon,etc perfectly. The X160-PEEK version applied to 3D printing of PEEK. We supply high quality PEEK filament as well , which requires 420°C extrusion temperature. The material have features of high strength, high toughness, corrosion resistance and wear resistance. It can be used in aerospace, electronics, medical, machinery, automotive and other industries.

X430標準版可完美列印PLA,ABS,尼龍等常規耗材,而X160-PEEK版 則可以列印PEEK耗材。我們提供高品質PEEK耗材,擠出溫度420°C。該材質可在250°C環境長期使用,具有超高強度,高韌性,耐腐蝕和耐磨損等優良特性, 可應用於航空航太,電子電器,醫療,機械,汽車等行業。

TECHNICAL SPECS

x430

|

PRINTING

Print Technology: Fused Deposition Modeling Build Volume:400* 300*300mm (X430) Number of Nozzles: Double Resolution:0.05mm Layer Resolution:0.02mm Filament Diameter:1.75mm Filament Compatibility: PLA, ABS, Carbon Fiber, Wood, Nylon, PC, PTEG, HIPS, PP, Flexible, TPU, PVA, PEEK, etc. Nozzle Diameter:0.4mm (0.3, 0.5, 0.6, 0.8, 1.0mm) Print File Type:GCO, GCODE TEMPERATURE Ambient Operating Temperature: 15-32°C Max. Nozzle Temperature:420°C Max. Bed Temperature:100°C Max. Cabinet Temperature:70°C SPEED Best Printing speed: 55mm/s Max. Printing speed: 180mm/s Max. traveling speed: 200mm/s |

MECHANICAL

Construction: Power-Coated Steel, Aluminum Casting for Motion Components, POM Build Plate: Heatable Aluminium PCB with BuildTak Build Plate Leveling:Automatic Extruder: Directly Drive Stepper Motors: 1.8° Step Angle with 1/16 Micro-stepping X Y Positioning Precision: 12.7 Microns Z Positioning Precision: 1.25 Microns ELECTRICALPower Requirements: 100-240V, 50-60Hz Max. Power: 300W Screen: 4.3" Touch Screen Control Chip: ATmega 2560 Storage Media: USB Disk Connectivity: USB |

SOFTWARE

Software Bundle: CURA Supported File Types: STL, OBJ, AMF Operating Systems: Windows (7,8,10) Mac OS X SPECIAL FUNCTIONOutage Restored: Sava data when power is off Filament Detection: Pause printing when filament run out Automatic Shut-down: Turn off the power automatically when printing is complete SIZE & WEIGHT Product Dimensions & Weight: 660*470*580mm 43Kg Packing Size & Weight:760*620*680mm 58Kg |

技 術 規 格

X430

|

列印參數

成型技術: 熔融沉積成型(FDM) 成型尺寸: 400*300*300mm 噴頭數量: 雙 列印精度: 0.05mm 最小層厚: 0.02mm 耗材直徑: 1.75mm 耗材類型: PLA、ABS、碳纖維、木制、尼龍、PC、PTEG、HIPS、PP、TPU、PVA、PEEK 等 噴嘴直徑: 0.4mm (0.3, 0.5, 0.6, 0.8, 1.0mm) 切片檔案類型: GCO, GCODE 溫 度 參 數 工作溫度: 15-32°C 噴頭最高溫度: 420°C 熱床最高溫度: 100°C 工作艙最高溫度: 70°C 速 度 參 數 最佳列印速度: 55mm/s 最高列印速度: 180mm/s 最高空程速度: 200mm/s |

機 械 參 數

主要組成材料: 塑鋼板、鋁合金、POM 等 工作臺: 碳纖維板敷面加熱鋁基板 工作臺調平: 全自動調平 擠出機: 近端送料 步進電機: 1.8° 步進角,1/16 細分 X Y 定位精度: 12.7 微米 Z 定位精度: 1.25 微米 電 氣 參 數 電源: 100-240V, 50-60Hz 最大功率: 300W 螢幕: 4.3" 彩色觸屏(多國語言) 控制晶片: ATmega 2560 存儲介質: USB隨身碟 連接: USB |

軟體參 數套裝軟體:

Cura多國語言 檔案類型: STL, OBJ, AMF 作業系統: Windows (7,8,10) Mac OS X 特 色 功 能斷電續打: 斷電時保存資料 耗材檢測: 耗材用盡時暫停列印 自動關機: 列印完成後自動關機 尺寸 & 重量產品尺寸 & 重量: 660*470*580mm 43Kg 包裝尺寸 & 重量: 760*620*680mm 58Kg |

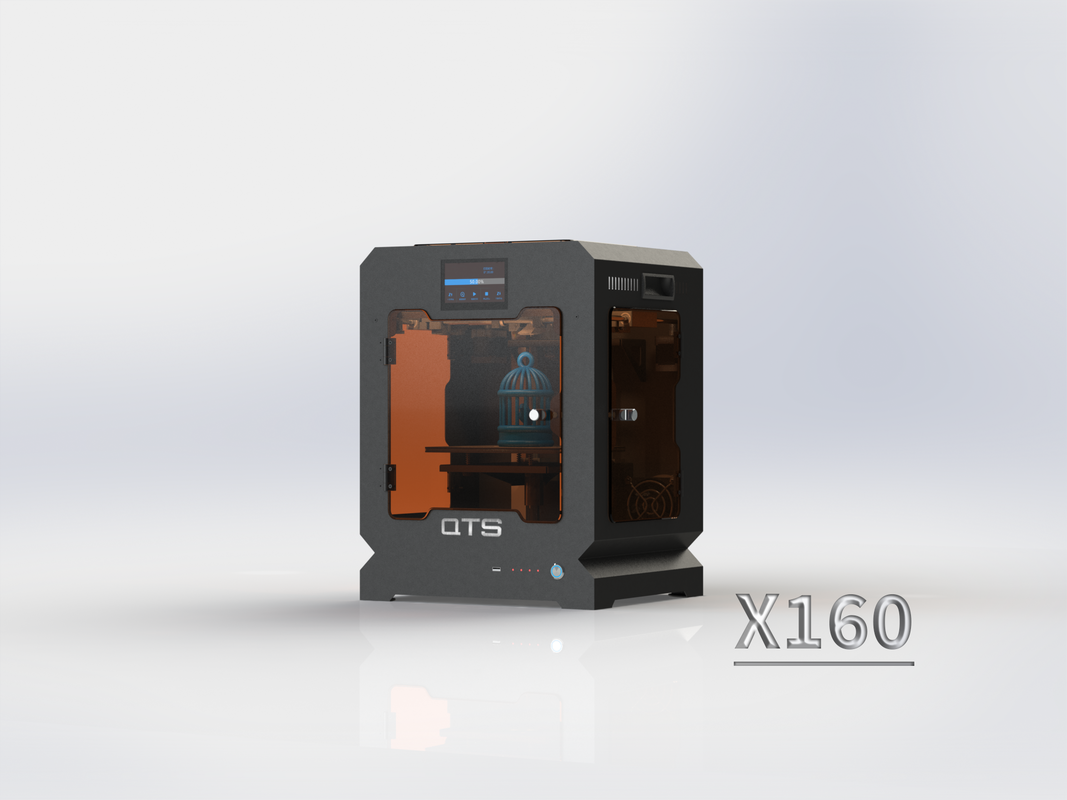

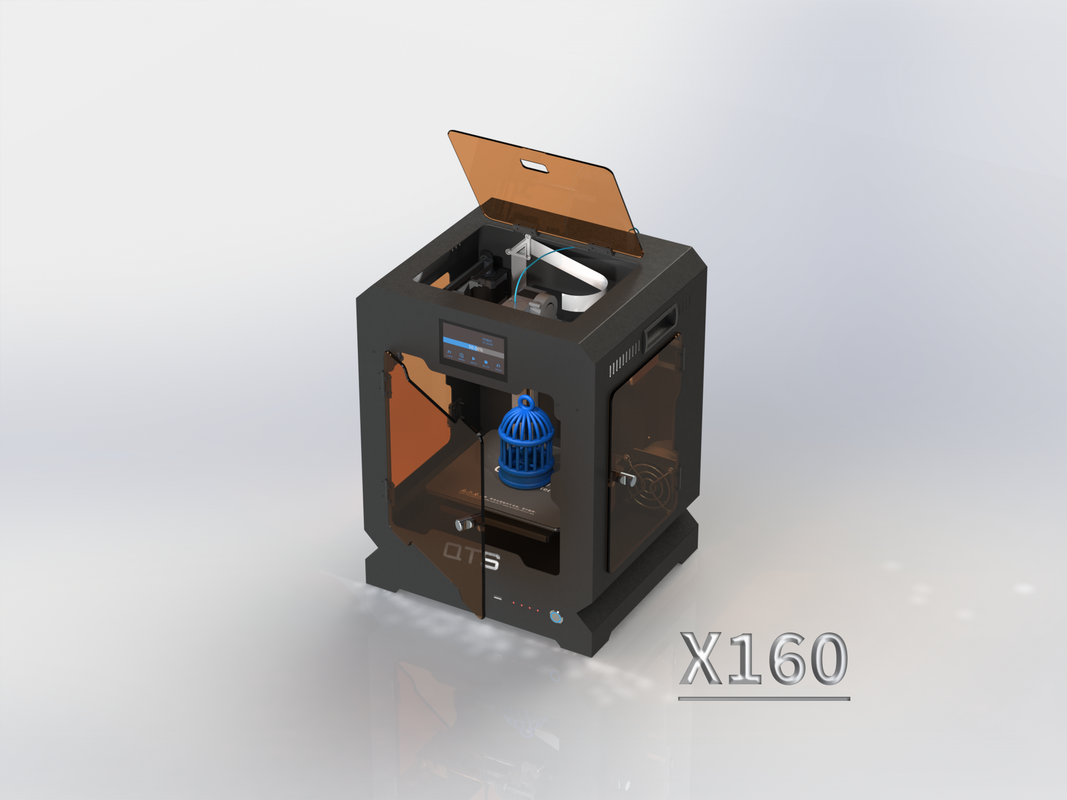

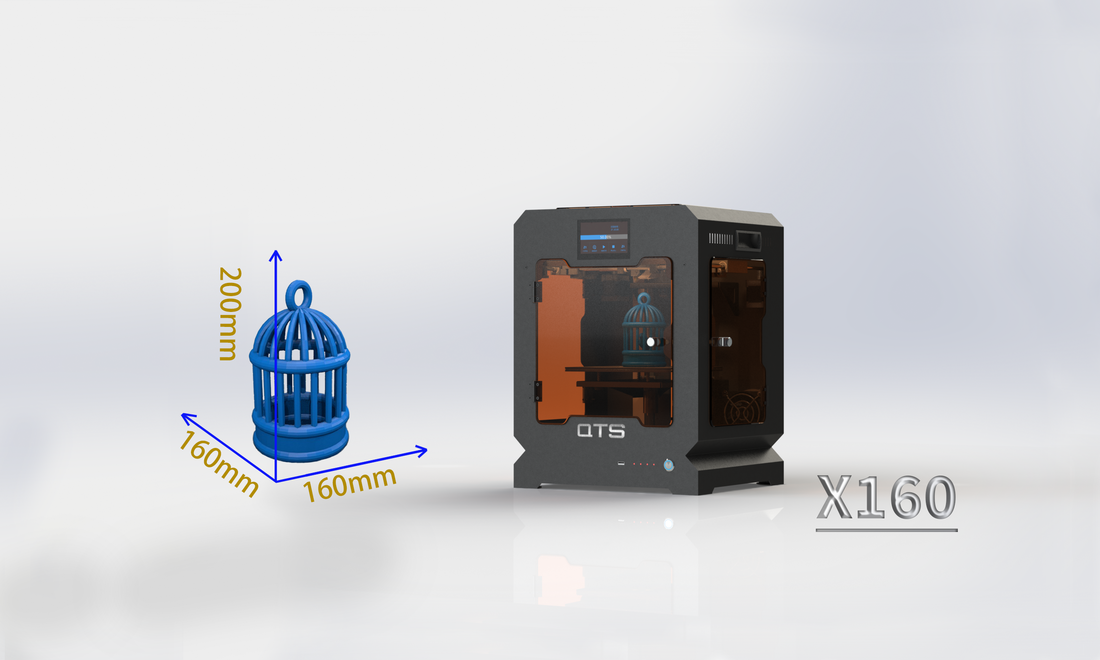

QTS X160 3D列印機

Support 420°C Hotend

支援 420°C 高溫噴頭

We are the first one to publish 420°C high temperature nozzle to 3d printer market. This kind of nozzle allow to print with a variety of filaments. The nozzle height can also be micro adjusted. (Default support 260°C, contact us for 420°C.

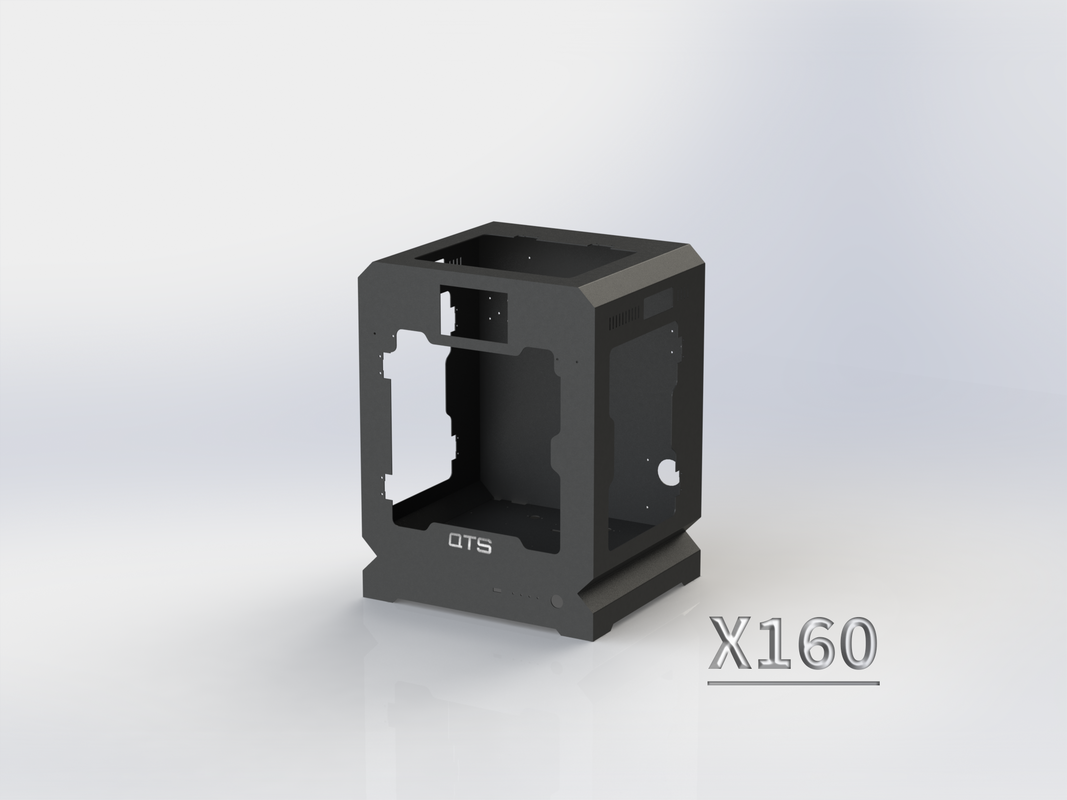

Stability

超強穩定性

The whole-steel body not only ensure the stability when printing, but also extend the usage period greatly. Its optimization and cooperation of overall structure ensure the sustainable and efficient operation. The first batch of QTS 3D printers have been working for 5 years and more than 8000 hours.

精鋼一體成型保證了機器的穩定性並極大延長了使用壽命。整體結構設計的優化和配合保證機器可持續高效運行。QTS 首批3D印表機已經持續工作 5 年,單台累計列印時間平均超過 8000 個小時。

Fully Enclosed High-Temperature Chamber

全封閉高溫艙

Fully enclosed chamber can block all external interference and reduce noise. Hot chamber can provide constant room temperature so that model won’t deform when printing.

主機殼全封閉,阻隔外界所有干擾。同時降低噪音,提供恒溫空間,使模型列印不翹邊。

Outage Restored & Filament Detection

斷電續印 & 耗材檢測

The printer will automatically memorize the current position and save print data. Lower the platform and withdraw filament when power off suddenly. It will continue to print from the last stopped point after power’s on.

The printer will avoid invalid printing by stoping print and warning when filament runs out.

The printer will avoid invalid printing by stoping print and warning when filament runs out.

意外斷電時印表機自動記憶當前位置,並儲存列印資料,降低工作臺並回抽。待電力恢復後從斷電處繼續列印。

耗材用盡後自動暫停列印,回抽耗材並發出提示音,避免無效列印。

耗材用盡後自動暫停列印,回抽耗材並發出提示音,避免無效列印。

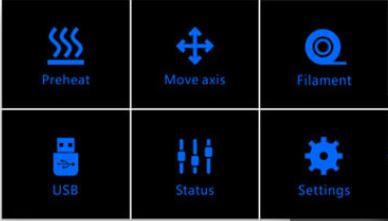

Touch Screen

彩色觸控式螢幕

The printer have all-English-menu touch screen which is easy operate and friendly use. One key to warm,one key to print as well as many other shortcut keys.

配備全彩中文觸控式螢幕,操作簡單,介面友好。提供一鍵預熱,一鍵列印等多種快捷操作。

Efficiently Platform & 130°C Hotbed

130°C 高溫工作臺

The hotbed is made of heatable aluminium PCB, which can be heat up to 130°C fast. The platform is attached with 3d printing stickers buildtak. Printed object can be stick on the buildtak tightly and won’t get deformed

鋁基板工作臺,可加熱至130°C,工作臺表面附著專用3D列印貼紙,熱傳導效率高,模型可有效粘固在工作臺上,防止模型翹邊。

TECHNICAL SPECS

|

PRINTING

Print Technology: Fused Deposition Modeling Build Volume: 160*160*200mm (X160) Number of Nozzles: Single Resolution: 0.04mm Layer Resolution: 0.01mm Filament Diameter: 1.75mm Filament Compatibility: PLA, ABS, Carbon Fiber, Wood, Nylon, PC, PTEG, HIPS, PP, Flexible, TPU, PVA, PEEK, etc. Nozzle Diameter: 0.4mm (0.3, 0.5, 0.6, 0.8, 1.0mm) Print File Type: GCO, GCODE TEMPERATURE Ambient Operating Temperature: 15-32°C Max. Nozzle Temperature: 420°C Max. Bed Temperature: 130°C SPEED Best Printing speed: 60mm/s Max. Printing speed: 200mm/s Max. traveling speed: 200mm/s |

MECHANICAL

Construction: Power-Coated Steel, Aluminum Casting for Motion Components, POM Build Plate: Heatable Aluminium PCB with BuildTak Build Plate Leveling: Manually Extruder: Directly Drive Stepper Motors: 1.8° Step Angle with 1/16 Micro-stepping X Y Positioning Precision: 12.7 Microns Z Positioning Precision: 1.25 Microns ELECTRICAL Power Requirements: 100-240V, 50-60Hz Max. Power: 300W Screen: 4.3" Touch Screen Control Chip: ATmega 2560 Storage Media: USB Disk Connectivity: USB |

SOFTWARE

Software Bundle: CURA Supported File Types: STL, OBJ, AMF Operating Systems: Windows (7,8,10) Mac OS X SPECIAL FUNCTIONOutage Restored: Sava data when power is off Filament Detection: Pause printing when filament run out Automatic Shut-down: Turn off the power automatically when printing is complete SIZE & WEIGHTProduct Dimensions & Weight: 370*320*490mm 20Kg Packing Size & Weight: 470*420*600mm 25Kg |

技 術 規 格

X160

|

打 印 參 數成型技術:

熔融沉積成型(FDM) 成型尺寸: 160*160*200mm (X160) 噴頭數量: 單 列印精度: 0.05mm 最小層厚: 0.01mm 耗材直徑: 1.75mm 耗材類型: PLA、ABS、碳纖維、木制、尼龍、PC、PTEG、HIPS、PP、TPU、PVA、PEEK 等 噴嘴直徑: 0.4mm (0.3, 0.5, 0.6, 0.8, 1.0mm) 切片檔案類型: GCO, GCODE 溫 度 參 數工作溫度: 15-32°C 噴頭最高溫度: 420°C 熱床最高溫度: 130°C 速度參數最佳列印速度: 60mm/s 最高列印速度: 200mm/s 最高空程速度: 200mm/s |

機械參數主要組成材料:

噴塑鋼板、鋁合金、POM 等 工作臺: BuildTak 敷面加熱鋁基板 工作臺調平: 手動調平 擠出機: 近端送絲 步進電機: 1.8° 步進角,1/16 細分 X Y 定位精度: 12.7 微米 Z 定位精度: 1.25 微米 電 氣 參 數電源: 100-240V, 50-60Hz 最大功率: 300W 螢幕: 4.3" 彩色觸屏(多國語言) 控制晶片: ATmega 2560 存儲介質: USB隨身碟 連接: USB |

軟體參數套裝軟體:

CreatWare 多國語言 檔案類型: STL, OBJ, AMF 作業系統: Windows (7,8,10) Mac OS X 特 色 功 能斷電續打: 斷電時保存資料 耗材檢測: 耗材用盡時暫停列印 自動關機: 列印完成後自動關機 |