Robotic Arm for Everyone

Arduino-based & Open Source

家用桌上型機械手臂機器人 DOBOT

#robotics #makers #robotic_arm #open-source #arduino

以下部分產品介紹內轉載自群眾觀點 及 Dobot官網

Robotic Arm for Everyone

Arduino-based & Open Source

家用桌上型機械手臂機器人 DOBOT

#robotics #makers #robotic_arm #open-source #arduino

以下部分產品介紹內轉載自群眾觀點 及 Dobot官網

之前 Kickstarter上有一款桌面型機器人產品引起了很多人的關注,

從Arduino的共同創始人到Twitter的前副總裁都在談論它。

它是誰?它是「Dobot機械手臂」!

Dobot的開發團隊是來自中國的6位工業機器人工程師。身為機器人狂熱愛好者,他們希望能用最低的成本,

製造出有最簡單控制方法,並能服務於桌面工作的機械手臂。雖然機器人手臂在目前行業中有廣泛的應用,

包括裝配鋼鐵、汽車、 精密手術等,不過由於高昂的價格和在操作中的困難,這些應用程序好像離我們的生活很遠。

如今,桌面機器人已經想簡化的結構和簡單的操作轉型,真正實現從大型工業應用到平民化市場。

也許是這一點點希冀,他們決定把整個機械臂的項目開源,旨在引進更多外力協同開發生產相關的邏輯應用,

把機械臂的功能和效率生產力最大利益化。他們最初的設想是做工業機器人,但這個行業競爭大,成本高,

關鍵部件價格被壟斷,所以決定發展三步曲,從桌面型機械手開始、到地面型、然後是最後實現家庭服務型。

Dobot,就是他們的第一步!

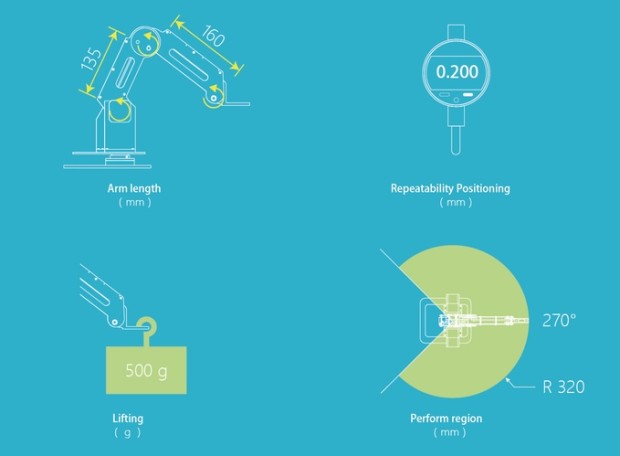

它是一款具有4軸高精度、高重複定位精度、且基於Arduino的開源機器人臂,

它可以畫、寫、移動、抓握東西,還能3D列印物品和食品,而且定位精度還能達到0.2毫米!

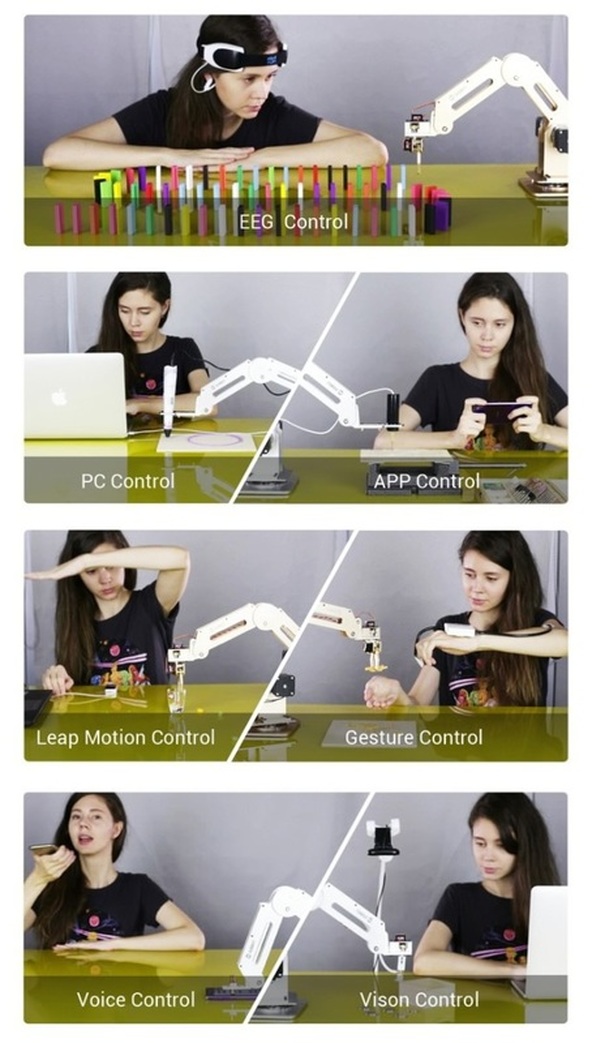

開發團隊為了讓Dobot做到盡可能地方便易用,為它設計了多達7種不同的控制方式,

包括 PC 控制,APP控制、腦電波(EGG)控制,語音控制,手勢傳感器,體感控制,與視覺識別!

包括 PC 控制,APP控制、腦電波(EGG)控制,語音控制,手勢傳感器,體感控制,與視覺識別!

而針對更高級的創客,Dobot提供了更多令人興奮的機會方便他們了解機器人技術和編碼,並將其用於自己的項目。

此外,該團隊還計劃使Dobot完全開源(它將支持三種類型的開源固件,包括 grbl 和 marlin),

這樣使用者可以自行修改、定製或者改進。他們還將持續編寫新的運動功能以添加到 Arduino 的功能庫裡。

此外,該團隊還計劃使Dobot完全開源(它將支持三種類型的開源固件,包括 grbl 和 marlin),

這樣使用者可以自行修改、定製或者改進。他們還將持續編寫新的運動功能以添加到 Arduino 的功能庫裡。

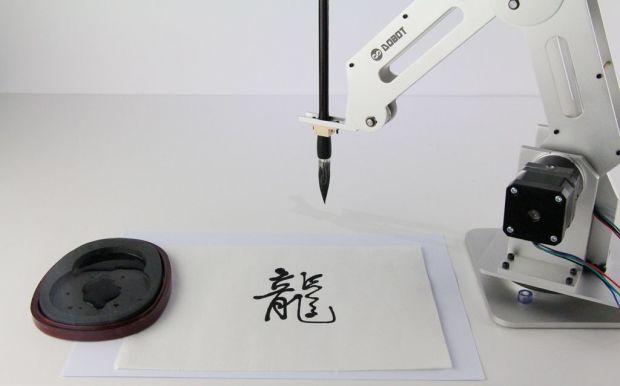

在影片中,你可以看到 Dobot 完成各種各樣的日常任務,比如在一塊麵包片上抹果醬、

為咖啡加糖、撥打智慧手機、與穿針引線等。甚至是幫你完成書法作業、書寫一封字跡優美的情書,以及製作各樣的繪畫與製作。

對於3D列印愛好者來說,Dobot還能變身為一台桌面3D列印機,自由地使用塑料和食品類線材進行3D列印。

為咖啡加糖、撥打智慧手機、與穿針引線等。甚至是幫你完成書法作業、書寫一封字跡優美的情書,以及製作各樣的繪畫與製作。

對於3D列印愛好者來說,Dobot還能變身為一台桌面3D列印機,自由地使用塑料和食品類線材進行3D列印。

開發團隊稱,這款Dobot桌面機器人很好地在成本和性能之間取得了平衡。

目前產業內的機器人手臂不少,一些低端的機械手採用舵機控制,只能實現定性運動,

無法定量控制,精度在10mm左右,現在只要兩三千元就買得到;而像ABB的機械手需要諧波減速器——這玩意一個就要兩萬多元,

且這類工藝應用需要工業應用要穩定工作1000-2000小時無故障,所以他們的售價為至少都要超過五六十萬台幣。

很明顯,這中間,有一個小藍海可以被發掘!

Dobot平衡了這兩種方案的優缺點,“我們購買了很多品牌的減速器,但沒有滿足我們的要求,

所以Dobot則是自己找中國國內特製的減速箱,連續工作幾百個小時沒問題,從而達到性能與成本的最佳平衡。”團隊負責人劉培超表示。

目前產業內的機器人手臂不少,一些低端的機械手採用舵機控制,只能實現定性運動,

無法定量控制,精度在10mm左右,現在只要兩三千元就買得到;而像ABB的機械手需要諧波減速器——這玩意一個就要兩萬多元,

且這類工藝應用需要工業應用要穩定工作1000-2000小時無故障,所以他們的售價為至少都要超過五六十萬台幣。

很明顯,這中間,有一個小藍海可以被發掘!

Dobot平衡了這兩種方案的優缺點,“我們購買了很多品牌的減速器,但沒有滿足我們的要求,

所以Dobot則是自己找中國國內特製的減速箱,連續工作幾百個小時沒問題,從而達到性能與成本的最佳平衡。”團隊負責人劉培超表示。

DOBOT 機械手臂 常見問題

|

1、DOBOT機械手臂是幾軸的,分別在哪個位置?

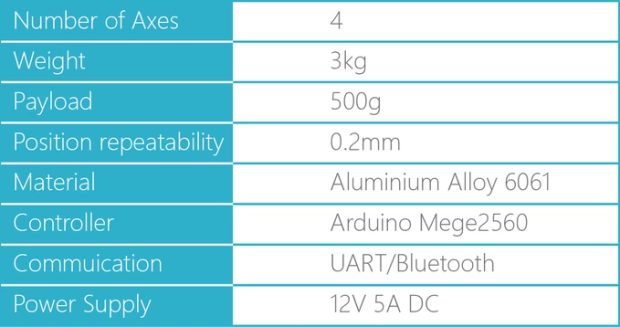

Dobot機械臂為4軸並聯結構機械臂,Joint1-Joint3使用步進電機, 分別對應於機械臂的底座、大臂、小臂;Joint4對應於末端夾具(機械爪、吸盤)的旋轉,使用舵機。 2、DOBOT機械臂的負載有多少? Dobot機械手臂的負載為500g。由於機械臂末端處於不同空間位置時力矩不同,所能承受的負載也會略微不同。 3、DOBOT機械手臂有多長? Dobot機械手臂臂展為320MM,具體機械臂運行空間請參考Dobot參數文檔。 4、Dobot機械臂重複定位精度是多少? Dobot機械手臂 重複定位精度為 ±0.1 mm。 5、Dobot機械臂發貨時包含哪些設備? Dobot機械手臂基本版套餐包含以下內容: 機械手臂主體、Dobot控制盒、5件夾具(機械爪、吸盤套件、電容筆、小楷筆與夾筆器、雷射頭與雷射固定座)、 電源供應器、USB鏈接線、工具包以及延長線、底座吸盤等附件。詳細信息請參考發貨清單。 6、Dobot機械手臂收到之後需要自己安裝嗎?安裝複不複雜? 您收到的Dobot機械臂是已經組裝好的,無需自己組裝,只需要將相應的連線按指示連接起來即可。 更多詳情請參閱,Dobot操作快速開始指引. 7、如何用Dobot機器人進行開發? Dobot 開放了底層通信協議,通過串口通信,可以直接配置運行參數,發送控制指令等來操作Dobot機械手臂。 我們也提供的了DobotTools軟件源代碼,可以作為您二次開發的參考樣例。 8、Dobot機器人是否開源? Dobot機器人底層代碼目前是不開源的,我們開放通信協議和DobotTools的代碼來支持二次開發。 最新的Dobot控制器採用了新版帶有FPGA的控制方案,解決了之前單獨Arduino mega 2560作為控制器時的失步和 誤差累計的問題。現有方案結果上千小時連續運行驗證穩定。然而現有方案對底層時序要求嚴格, 開放底層代碼會對機械手臂運行的安全性和穩定性產生影響,所以目前推薦大家通過串口通信來接入新的感測器、 控制器等。更多可查看Dobot API. 9、如何使用外設與Dobot機械手臂相連?如添加傳感器, 開關信號等? 可以將外設與傳感器連接到另外一塊獨立的微控制器上進行傳感器數據的採集和處理, 以及相應的邏輯判斷,然後再通過微控制器與Dobot控制器進行串口通信的方式進行開發處理。 10、可否使用Arduino/ PLC/ ARM等微控制器來控制Dobot機械手臂? 可以使用,只需要將相應微控制器與Dobot機械手臂的藍牙模塊鏈接的串口相連, 按照Dobot通信協議向Dobot發送控制指令即可。 11、Dobot機械臂是如何進行通信與控制的? Dobot控制器提供了USB與藍牙兩種通信方式,分別對應於Arduino mega 2560的兩個串口: (1)在PC端安裝aruidno驅動之後,電腦端可以通過USB轉串口,與Arduino控制器進行通信。 (2)Android/iOS設備可以通過藍牙與控制器板載藍牙模塊相連 (android端需要輸入配對密碼:1234, iOS app 不需要密碼配對),將控制指令發送給Dobot控制器。 (3)藍牙模塊端口對應的串口亦可以作為與其他微控制器通信的串口端口。 外部微控制器只需要按照通信協議給Dobot控制器發送控制指令即可。 12、Dobot機械手臂無法運動時 1. 檢查傳感器是否正確安裝與連接。 2. USB撥碼開關是否連接到USB端(如果是用手機控制 需要撥到Bluetooth端) 3. 連接USB線,打開軟件,查看軟件是否提示“Not found serial port!”,若出現以上提示, 請安裝Arduino驅動,若Arduino驅動安裝正常,可在設備管理器中看到名為“Arduino mega 2560”的設備。 4. 根據版本進行Baud Rate進行配置(1.1及以後版本為9600)。 5. 檢查機械臂是否處於限位位置,請將機械臂大小臂致於大約45度處,在復位後重新測試。 6. 進入teach&playback界面joint2&3上面空格是否有數字,若經過以上步驟, joint2&3仍然未有數字可以嘗試用DobotTools中的下載固件下載最新版的固件,然後再次嘗試。 7. 如果經過以上步驟還沒解決,請直接聯繫 info@qts.tw,我們會盡快為您解答。

|

For DESKTOP. Arduino-based, 4-axis parallel-mechanism Robot Arm,

0.2mm precision! Bring industrial robot to everyone. Effective tool.

Short Summary

Our dream is to bring the industrial robot arm to daily life,

let everyone can enjoy the joy of it and simplify the life from doing repetitive tasks.

So we tried to creat a high repeat precision (up to 0.2mm),

stepper motor, Arduino-based, easy to control ( 7 controlling methods),

low-cost desktop robotic arm. It calls Dobot.

How Dobot Arm make the magic happen?

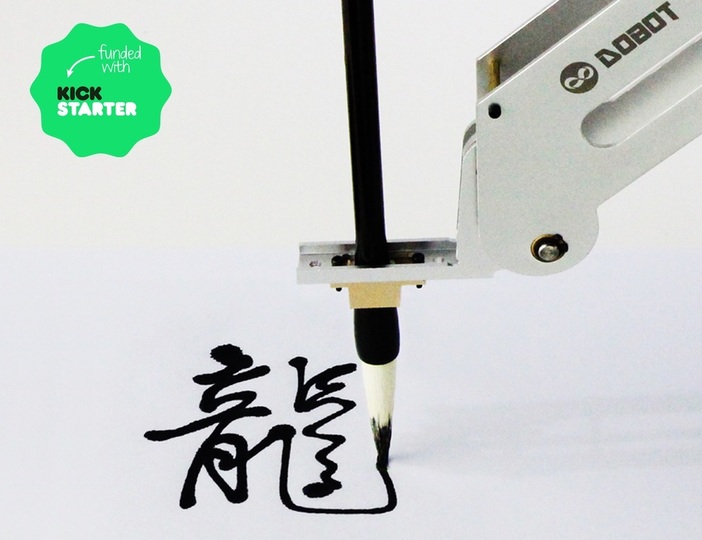

Imagine when your new born baby says "flower" the first time in his/her life,

and it gets sent to a Arduino robotic arm, automatically the word transforms to the character

龙 (dragon, see the gif below) in Chinese calligraphy on a piece of paper or a 3D printed plastic flower,

or be typed on a mobile phone that sends to your parents.

0.2mm precision! Bring industrial robot to everyone. Effective tool.

Short Summary

Our dream is to bring the industrial robot arm to daily life,

let everyone can enjoy the joy of it and simplify the life from doing repetitive tasks.

So we tried to creat a high repeat precision (up to 0.2mm),

stepper motor, Arduino-based, easy to control ( 7 controlling methods),

low-cost desktop robotic arm. It calls Dobot.

How Dobot Arm make the magic happen?

Imagine when your new born baby says "flower" the first time in his/her life,

and it gets sent to a Arduino robotic arm, automatically the word transforms to the character

龙 (dragon, see the gif below) in Chinese calligraphy on a piece of paper or a 3D printed plastic flower,

or be typed on a mobile phone that sends to your parents.

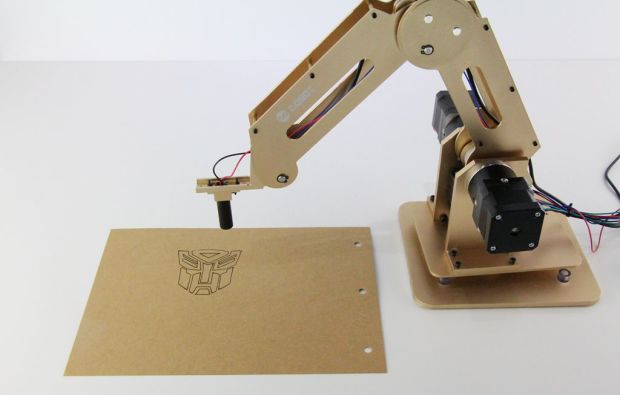

As makers, we love tools. Dobot robot arm will play a big role being a good tool,

you can grave a film figure by yourself with the help of Dobot arm,

sounds cool, isn't it? DIY the Transformers, Baymax, Mario or other figure you like now !

you can grave a film figure by yourself with the help of Dobot arm,

sounds cool, isn't it? DIY the Transformers, Baymax, Mario or other figure you like now !

3D printing pen works with Dobot

With the high repeatability of Dobot, Dobot robotic arm can well

work with 3D printing pen to print anything you want!

Why Choose Dobot Arm?

Dobot Brings Industrial Precision and Power to Your Life

Dobot’s high precision is the highlight. We spent much of our energy to optimize its technology.

With such a low cost, we have managed to maintain the industrial precision level.

When performing repetitive actions, the error in precision is as small as 0.2mm,

empowering you to do delicate work without losing the precision. See below for more detailed info on specs.

Dobot is Super Easy to Control

Easy usability comes first during the design of Dobot.

We have given a lot of thought on users without technical backgrounds,

and how to help them better control robotic arms.

In order to make as young as 5-years-old kids able to use Dobot in ease,

we have done extensive research and designed 7 controlling methods, including PC,

mobile APP, EEG, voice, vision, leap motion and gestures, whichever suits your purpose the best.

Easy usability comes first during the design of Dobot.

We have given a lot of thought on users without technical backgrounds,

and how to help them better control robotic arms.

In order to make as young as 5-years-old kids able to use Dobot in ease,

we have done extensive research and designed 7 controlling methods, including PC,

mobile APP, EEG, voice, vision, leap motion and gestures, whichever suits your purpose the best.

Stepper motor: Dobot works quietly

We have also considered on where the users will be using it,

and tired our best to make the noise level as low as possible.

By using customized stepper motor, we are able to minimize noise level,

making Dobot much quieter than low-cost servo robotic arms and more household-friendly.

We have also considered on where the users will be using it,

and tired our best to make the noise level as low as possible.

By using customized stepper motor, we are able to minimize noise level,

making Dobot much quieter than low-cost servo robotic arms and more household-friendly.

Dobot is open source

As a group of devoted open source fans, we believe open source makes

the world better by levering the power of collective minds.

Yet to help you understand better of what we do, we are working around the clock on some

of the code that need more notations and explanations.

But we make our promise here that after the indiegogo campaign,

we will upload the code. Keep in touch, there are more surprises to come.

As a group of devoted open source fans, we believe open source makes

the world better by levering the power of collective minds.

Yet to help you understand better of what we do, we are working around the clock on some

of the code that need more notations and explanations.

But we make our promise here that after the indiegogo campaign,

we will upload the code. Keep in touch, there are more surprises to come.

Even More Exciting For Makers!

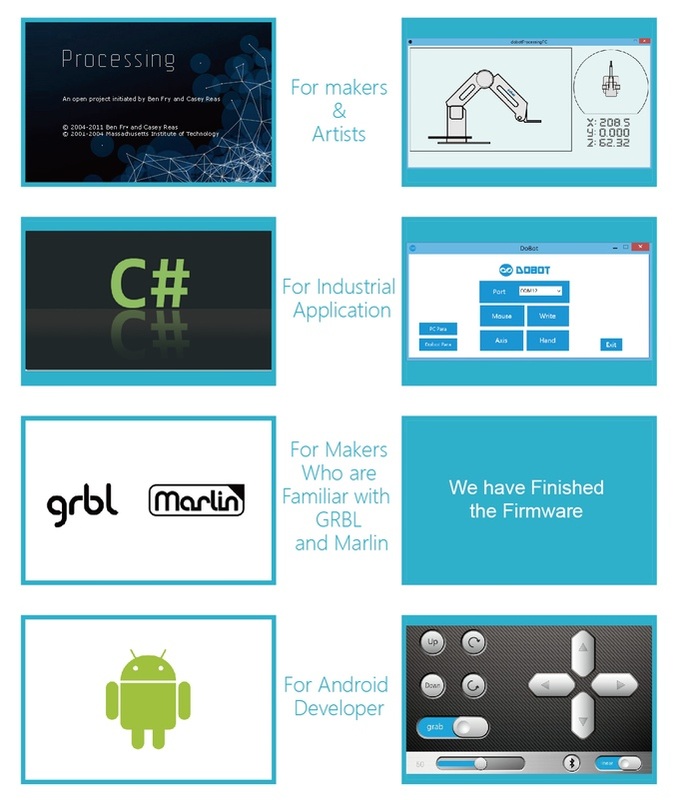

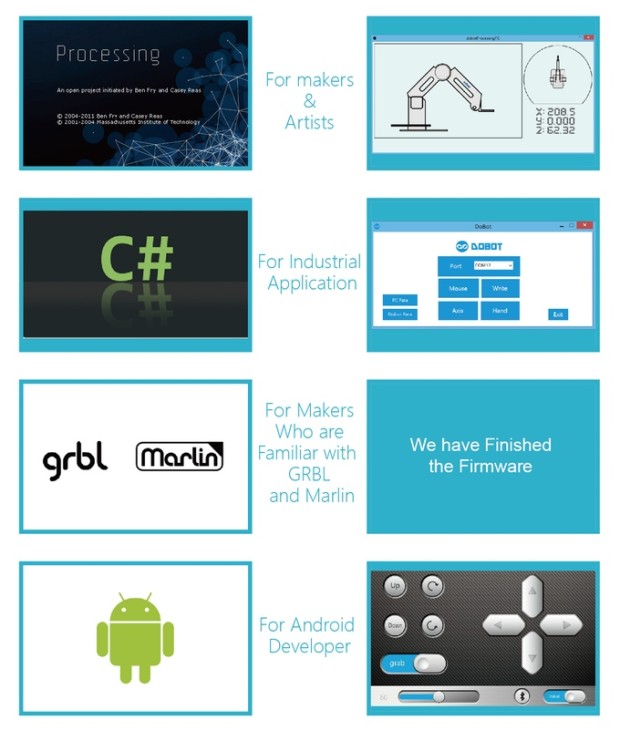

Dobot supports three OpenSource Firmware for special applications and developers with different programming preferences.

1. Complete developed by Dobot team Easy for developers familiar with Industrial robots.

2. Base on grbl (https://github.com/grbl/grbl) Easy for developers familiar with open source CNC machine.

3. Base on Marlin (https://github.com/MarlinFirmware/Marlin) Easy for developers familiar with RepRap compatiable 3D printer.

Also we provide communication interface for OpenCV (http://opencv.org/) to add vision to Dobot.

Dobot supports three OpenSource Firmware for special applications and developers with different programming preferences.

1. Complete developed by Dobot team Easy for developers familiar with Industrial robots.

2. Base on grbl (https://github.com/grbl/grbl) Easy for developers familiar with open source CNC machine.

3. Base on Marlin (https://github.com/MarlinFirmware/Marlin) Easy for developers familiar with RepRap compatiable 3D printer.

Also we provide communication interface for OpenCV (http://opencv.org/) to add vision to Dobot.

Dobot is a maker team and we create what's best for makers.

We use Arduino as the controller. Although when tackling some critical problems,

we found this might not be the perfect solution, after continuous improvements,

we believe this could equip superb functionality with Dobot.

We use Arduino as the controller. Although when tackling some critical problems,

we found this might not be the perfect solution, after continuous improvements,

we believe this could equip superb functionality with Dobot.

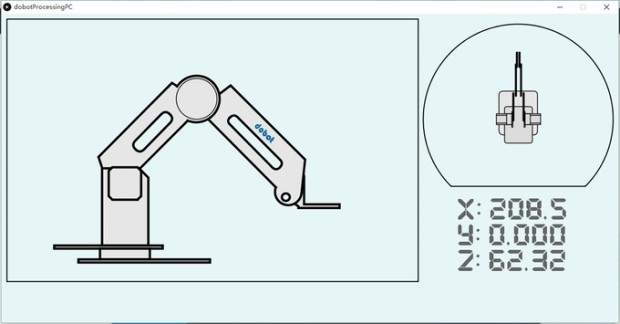

Processing is the widely-applauded data visualization and programming platform for beginners.

Simply drag and click, you can program Dobot at your will on its user-friendly interface.

Simply drag and click, you can program Dobot at your will on its user-friendly interface.

Scratch is also a briiliant visual programming language that's more widely used by children,

artists and makers. It helps them to control and program all types of electronic devices and interactive products.

Dobot's control is based on the easy-for-understanding serial communication protocol whose working principles are all open-sourced.

We will add more manpower in developing control extensions based on Scratch,

and believe this will make operating Dobot applications easier for children, enabling them to bring their ideas to life.

Arduino Library

We have included diversified written motion functions for user to make their own Dobot code community.

We’ve included forward and inverse solution, point to point, line, jump Path Planning, everything is open source,

and you can make it better. These code examples have very similar principles to industrial robot developing

and they are very useful for one who wants to understand how an industrial robot works.

In our code, we provide the limit and working range protection, various joint and coordinate commands,

combine these functions and you are the magician.

Electronic Parts

Our initial thought was to design a shield for the Arduino (Mega2560) for connecting mega2560 and

3 stepper driver boards and also to contain a current amplifying module to drive the vacuum pump

and the solenoid valve. Meanwhile, it can manage driving 2 servos with 3 steppers. Based on that,

we modified the design to accommodate more users, thus another shield of Arduino was born to

satisfy all of the above functions. This eliminates the constitute of stepper driver boards

and reconsiders the measures for overcurrent protection and heat dissipation.

Our core competency is to employ fewer wires with a better outlook ensured.

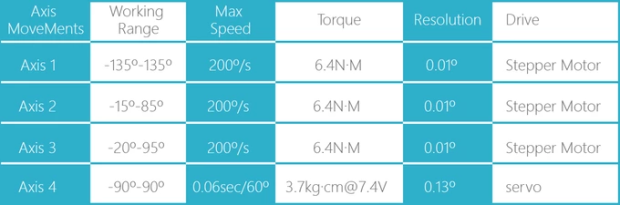

Tech. Spec.

artists and makers. It helps them to control and program all types of electronic devices and interactive products.

Dobot's control is based on the easy-for-understanding serial communication protocol whose working principles are all open-sourced.

We will add more manpower in developing control extensions based on Scratch,

and believe this will make operating Dobot applications easier for children, enabling them to bring their ideas to life.

Arduino Library

We have included diversified written motion functions for user to make their own Dobot code community.

We’ve included forward and inverse solution, point to point, line, jump Path Planning, everything is open source,

and you can make it better. These code examples have very similar principles to industrial robot developing

and they are very useful for one who wants to understand how an industrial robot works.

In our code, we provide the limit and working range protection, various joint and coordinate commands,

combine these functions and you are the magician.

Electronic Parts

Our initial thought was to design a shield for the Arduino (Mega2560) for connecting mega2560 and

3 stepper driver boards and also to contain a current amplifying module to drive the vacuum pump

and the solenoid valve. Meanwhile, it can manage driving 2 servos with 3 steppers. Based on that,

we modified the design to accommodate more users, thus another shield of Arduino was born to

satisfy all of the above functions. This eliminates the constitute of stepper driver boards

and reconsiders the measures for overcurrent protection and heat dissipation.

Our core competency is to employ fewer wires with a better outlook ensured.

Tech. Spec.

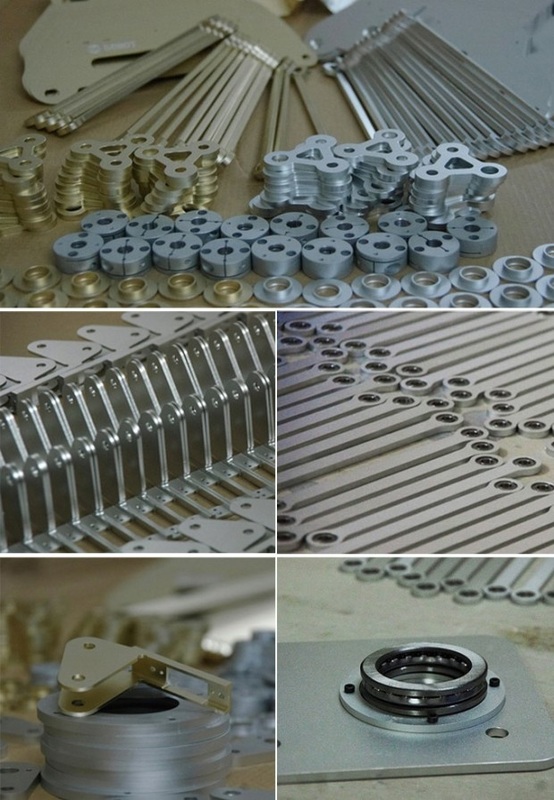

The Quality Assurance

Mechanical Parts

How Dobot is made and how we made its incredible precision level possible.

The mechanical structure entirely employed CNC cutting technology.

For key parts the machinery accuracy has reached 0.02mm.

Joint connections adopted high accuracy axes coupled with chrome alloy interference lit,

ensuring structural stability and accuracy. On the motor side,

Dobot designed the high accuracy speed reducer motor,

providing consistent motor power for the robot arm.

On the material side, Dobot was made of high strength aluminium alloy and

processed by anodic oxidation treatment, to ensure the sleekness and strength of the surface.

For key parts the machinery accuracy has reached 0.02mm.

Joint connections adopted high accuracy axes coupled with chrome alloy interference lit,

ensuring structural stability and accuracy. On the motor side,

Dobot designed the high accuracy speed reducer motor,

providing consistent motor power for the robot arm.

On the material side, Dobot was made of high strength aluminium alloy and

processed by anodic oxidation treatment, to ensure the sleekness and strength of the surface.

Here's some details about the manufacturing, we chose the high performance CNC

machine instead of laser cut to guarantee a 0.02mm precision, which provides the basis of our high quality.

machine instead of laser cut to guarantee a 0.02mm precision, which provides the basis of our high quality.

For software, we have done a great deal of optimization.

The software supports speed look-ahead small line blocks interpolation algorithm,

able to fit any type of curve and ensure processing efficiency. Moreover,

with the Three Axes Linkage Method fine interpolation, you can control the trajectory

of the end effector of the Dobot accurately, empowering it with complex curvilinear motions.

The software supports speed look-ahead small line blocks interpolation algorithm,

able to fit any type of curve and ensure processing efficiency. Moreover,

with the Three Axes Linkage Method fine interpolation, you can control the trajectory

of the end effector of the Dobot accurately, empowering it with complex curvilinear motions.