- Functional Resins

- >

- QTS AS Beige UV 3D Printer 405nm Resin

QTS AS Beige UV 3D Printer 405nm Resin

SKU:

$28.80

$24.80

$24.80

無法使用

每件商品

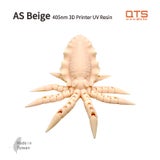

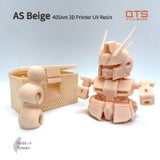

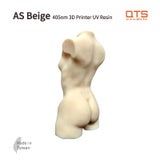

AS series is a scratch-resistant skin tone liquid UV-curable photosensitive resin with high-resolution details. Especially on the female muscle model, the slenderness and beauty of the female body can be perfectly presented, which is suitable for the new type of high-intensity (4K, 8K) LCD and DLP printing equipment with a wavelength of 395~405nm. This material has less shrinkage, is easy to clean, and the surface is gentle and non-reflective. It is especially suitable for the development of models for printing high-resolution cartoon characters. After the material is fully post-cured, the surface is scratch-resistant, not easy to turn white and powder, and has a smooth feel, which is especially suitable for female body models that are no longer colored.

◼ Download The Catalog

◼ Download The Catalog

|

◼ APPLICATION

- Anime character model - Character head sculpture - Female body skin appears |

◼ MODEL PROPERTIES

Physical properties of liquid materials Appearance Liquid complexion Density 1.10~1.15g / cm³ Viscosity 300~350cps@25℃ |

◼ CHARACTERISTICS

- Moderate viscosity, good fluidity, and clear printing details.

- Fast curing speed, wide printing parameters, saving printing time.

- Easy to clean, cave and surface texture are perfectly presented.

- Add nano-meter materials to reduce the problems of sedimentation and floating separation.

- The printed parts have a balanced adhesion to the carrier, which is easy to disassemble and will not be pulled off from the carrier.

- Dark gray with high resolution, excellent photo effects.

◼ POST-CURING

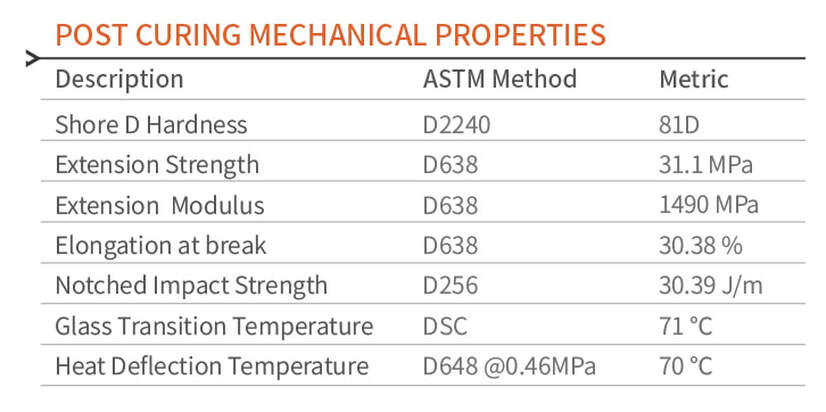

This material must undergo sufficient post-curing treatment after molding to achieve the best mechanical properties and surface dry and wear-resistant properties.

. 365~405nm UV post-curing in the light box for 10~60 minutes (depending on the color and thickness of the material, the thicker the thickness, the longer the post-curing time is required). It is not enough to use sunlight as the post-curing.

. It is recommended to use a UV post-curing lamp for 3D printing in order to achieve the best results.

. If it can be combined with heat curing at 60°C / 60 minutes, the toughness will be better.

◼ INSTRUCTIONS FOR USE

- Before use, be sure to shake and mix well to avoid long-term precipitation.

- This material is a light-curing chemical. Rubber gloves must be worn during operation to avoid long-term contact with the skin to avoid allergies and itching.

- The exposure parameters of different brands of models will be different. It is recommended to print a calibration film to confirm whether the exposure parameters are appropriate for the first use.

- After this material is printed and formed, it is suitable for cleaning with alcohol, isopropanol or a special cleaning agent.

- Moderate viscosity, good fluidity, and clear printing details.

- Fast curing speed, wide printing parameters, saving printing time.

- Easy to clean, cave and surface texture are perfectly presented.

- Add nano-meter materials to reduce the problems of sedimentation and floating separation.

- The printed parts have a balanced adhesion to the carrier, which is easy to disassemble and will not be pulled off from the carrier.

- Dark gray with high resolution, excellent photo effects.

◼ POST-CURING

This material must undergo sufficient post-curing treatment after molding to achieve the best mechanical properties and surface dry and wear-resistant properties.

. 365~405nm UV post-curing in the light box for 10~60 minutes (depending on the color and thickness of the material, the thicker the thickness, the longer the post-curing time is required). It is not enough to use sunlight as the post-curing.

. It is recommended to use a UV post-curing lamp for 3D printing in order to achieve the best results.

. If it can be combined with heat curing at 60°C / 60 minutes, the toughness will be better.

◼ INSTRUCTIONS FOR USE

- Before use, be sure to shake and mix well to avoid long-term precipitation.

- This material is a light-curing chemical. Rubber gloves must be worn during operation to avoid long-term contact with the skin to avoid allergies and itching.

- The exposure parameters of different brands of models will be different. It is recommended to print a calibration film to confirm whether the exposure parameters are appropriate for the first use.

- After this material is printed and formed, it is suitable for cleaning with alcohol, isopropanol or a special cleaning agent.

|

|

|